FRAC SAND TESTING

API RP 19C

Determination of - and standards for - frac sand specs are outlined in API RP 19C: “Measurement of Properties of Proppants Used in Hydraulic Fracturing and Gravel-packing Operations”. The standards detail the following frac sand testing procedures to determine if frac sand meets accepted specs:

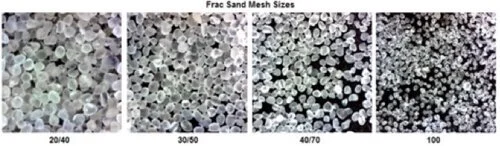

Sieve Analysis

With any raw, prospective frac sand sample, analysis of the frac sand sample begins with sieve testing to determine how much of the sand falls within typical frac sand size designations. The frac sand is run through a stack of defined ASTM sieves to give a detailed size distribution of the sand determining which products could be developed out of a prospective source.

Historically, common mesh sizes were 20/40 and 30/50 frac sand products, but there’s has been an increasing demand for finer grade frac sands meeting 40/70 and 70/140 specs. “100 mesh” is a common product, but the frac sand specs for this product are not defined in the API standards. It could refer to a defined 70/140 product or something a bit coarser such as 50/140 or 40/140 (i.e. “Heavy” 100 mesh).

When it comes to determining if an actual frac sand product meets accepted frac sand specs, at least 90% of the frac sand must fall within the marketed mesh size.

Sphericity and Roundness

The sphericity and roundness frac sand spec describe the overall shape of the frac sand.

Sphericity measures how close the proppant approaches the shape of sphere while roundness measures the relative sharpness of corners and curvatures of the frac sand.

The Krumbein and Sloss chart shown below is used in the sphericity and roundness frac sand testing assessment. Sand particles are compared to the chart while viewing under a microscope. The API RP 19C frac sand manual recommends a sphericity of 0.6 or above and a roundness of 0.6 or above for frac sand.

KRUMBEIN AND SLOSS CHART TO TEST FRAC SAND SPHERICITY AND ROUNDNESS.

Computerized Particle Analysis (CPA)

Computerized particle analysis (CPA) has become an increasingly more common means determining frac sand size distribution and sphericity and roundness. It can be a very quick measurement of size and shape frac sand specs making it a great option for QA/QC at the load out of a frac sand mine.

Thousands to millions of particles can be run through the CPA machine. Size and shape properties of each passing frac sand particle are measured and the CPA machine outputs stats for the entire sample. While typical sphericity and roundness frac sand testing are subject to the human eye, computerized particle analysis can provide a non-biased, quantitative assessment of sphericity and roundness frac sand specs.

Acid Solubility

The acid solubility frac sand test determines how the frac sand reacts when coming into contact with acid. It is an indication of the amount of non-silica contaminants in the frac sand. The API frac sand specs recommend the maximum percent (%) by weight of the frac sand that can be soluble in acid: 2% or less for frac sand mesh sizes 6/12 through 30/50 and 3% or less for frac sand mesh sizes 40/70 through 70/140.

Turbidity

Turbidity is the measure of suspended particles, such as clay or silt, in distilled water. The turbidity frac sand spec is essentially an indication of how dirty the frac sand is. It is possible that a more thorough washing process could reduce turbidity.

The API RP 19C recommends that frac sand turbidity be 250 FTU (Formazin Turbidity Unit) or less while measured using a turbidimeter.

Bulk Density

The bulk density of a sample is used to determine the mass of frac sand needed to fill a unit volume such as a fracture or storage tank as outlined in the API RP 19C.

Crush Resistance

Frac sand crush testing is used to determine the crush resistance of the proppant.

The frac sand is crushed at a predetermined stress and then sent back through the sieve analysis to determine the percentage of fines that were produced from the original sample that was crushed.

The crush resistance k-value frac sand spec the highest stress level at which proppant generates no more than 10% fines. This is an important metric when determining if a new sand source could meet industry-accepted frac sand specs.

Additionally, API RP 19C contains specifications for the maximum percentage of fines produced for each mesh size under a defined stress:

| Mesh Size of Sand | Stress on sand (in PSI) | Suggested maximum fines (% by weight) |

|---|---|---|

| 6/12 | 2,000 | 20 |

| 8/16 | 2,000 | 18 |

| 12/20 | 3,000 | 16 |

| 16/30 | 3,000 | 14 |

| 20/40 | 4,000 | 14 |

| 30/50 | 4,000 | 10 |

| 40/70 | 5,000 | 8 |

| 70/140 | 5,000 | 6 |